★ Industrial ARM chip, low power consumption, low heat, steady hardware.

★ Can set preheat delay, pierce torch up/down delay, pierce delay and so on.

★ Have functions of kerf compensation, breaking point recover, selection of pierce point, outline run and so on.

★ Have functions of cutting program pretreatment, gear adjustment, automatic speed down at the corner and so on.

★ Chinese and English.

★ There is a list of figures to use and array.

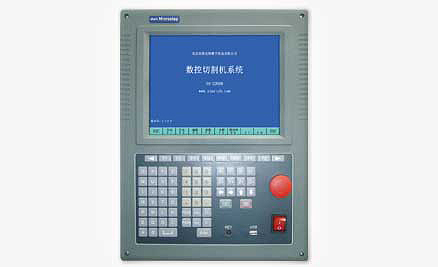

SH-2200H flame/plasma cutting controller is specially for gantry cutting machines, with 10.4″ color LCD and integrated keyboard panel.

Technical Parameters

★ No. of Linkage Axis: 2-4 axes

★ Highest Speed: 24m/min

★ Pulse Equivalence: gear numerator/denominator (1-65535)

★ Minimum Programming Unit: 0.001mm

★ I/O Control: 16*optoelectronic isolation, 14*optoelectronic isolation

★ Store Space: 64-512M

★ Expansion Port: USB, RS232, standard keyboard

★ Display: 10.4″ color LCD

★ Dimension: 310*410*83mm

★ Working Temperature: 0℃ ~ 55℃

★ Store Temperature: -40℃ ~ 60℃

★ You can choose any figure from the list and then array and create the program code.

★ You can rotate, scale, mirror and move the figure.

★ You can array the figure and create a new program.

★ You can align the plate and find the cutting start point.

★ The figure interface can greatly improve efficiency.